| Kieselhorst (The Restoration of a Family Heirloom Player Piano) |

|

To accomplish a proper

restoration, the entire piano was taken totally apart. All of the removable

case parts were taken to the local strippers and the sides which were

attached to the harp frame and soundboard were hand stripped. The case

was sanded re-stained, sealed and several coats of clear lacquer were

applied. |

|

|

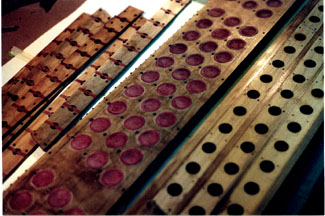

A tracing had been made of the decal on the fall board. This drawing was sent to "Decals Unlimited" in Minnesota, and a new decal was reproduced. All metal parts were nickel plated while the unit was taken apart. The player action was a very different "can of worms." All of the the deck boards, pneumatic, rods and levers went together very well and every part was assembled as it was intended. The images below shows |

|

this finished player pneumatic stack

waiting for the valve section to be restored, so it could be put on the

assembly with the air motor and the other mechanical roll playing parts. |

|

|

|

Some player piano actions are very hard, if not impossible, to restore. Many small player piano company's invented different ways to skirt patents held by the large player piano companies. Many of the resulting vintage actions ended up being Rube Goldberg in that they found the hardest way to do the simplest task. Try as I may, I could not restore the valve system from this piano so it would play the piano using the foot pumps, a requirement set forth by my client. |

|

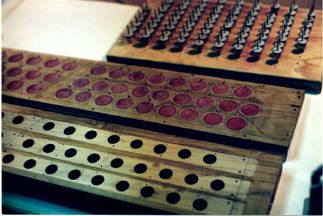

The new valve section I

eventually built, was made of poplar and used the moving valve spindles

of the vintage valve system. When finished the new valve stack screwed

into the same place on the pneumatic section as the |

|

|

vintage valve system did. All of the pieces fit exactly as they had before and from the outside, the unit looked just like the vintage valve system looked. The biggest difference was the Aeolian style pouch board setup and brass valve rods and guides. These were of my design to fit the needed spacing of the pneumatics action. |  |

|

The most important difference was that my new valves system could be actuated using the pumper peddles as required. The final step in the restoration was the need repairs on the piano action . As with every old action this one needed some TLC, as well as new bridal straps and hammer reshaping. The action was checked for any |

|

loose or broken parts and the ones found were replaces. In the end, I was very happy to put my name on this restoration. Footnote: After seeing my personal orchestrion, my client asked if I would build her a custom cut glass roll door to fit her piano. The window design allowed the glass door be closed but gave a view of the paper roll as the unit was playing. This window was made and installed as asked, before the piano delivery to her estate. |

|

(Rev.02-2006)

|

Click on the "Orchestrion" Icon to link to view This Studio 801Project. |  |

Click on the Resume" Icon to return |  |

Click on the "Home Page" Icon to return to the "Studio801" home page |